A thank you to our industry partners:

- Bristol Seafood, Portland, ME

- Channel Fish Processing, Braintree, MA

- North Coast Seafood, Boston, MA

- Raw Seafoods, Fall River, MA

Due to inclement weather, all classes at Northeastern University are canceled for today, Tuesday, February 28, 2023. Click here for additional information. Test

This is a four-year research endeavor on the topic of Design for Human-Robot Collaboration. Specifically, the research is looking at human-robot collaboration in the context of the industrial workplace, using the seafood processing industry in the American Northeast as a case study.

Designs, Tools and Methods for Enhanced Worker Experience

Machines in industrial workplace environments have notoriously been a source of harm for human health. Machines in gyms, instead, can help improve both health and fitness. This observation has been the starting point for this project. As people make use of machines in gyms or similar exercise setups to improve their health, why not take inspiration from that and develop machines for the factory floor that do the same?

This project leverages sensor-based technologies to monitoring human physique, condition, and behavior in real time to dynamically adjust to these differences for physical collaboration between a human worker and a robot in industrial workplace environments. We analyzed human movements and behavior on the factory floor and identified work tasks that resembled fitness routines. Leveraging a human-robot collaborative setting, we sought to emulate the fitness routine experience in a workplace-related task.

Principal Investigators: Kristian Kloeckl, Taskin Padir, Kemi Jona, Alicia Modestino, John Basl

This project is developed by the Experience Design Lab and the Institute for Experiential Robotics at Northeastern University. This work was supported by the National Science Foundation under the award number 1928654. Development of the prototype takes place in our space at innovation hub MassRobotics in the Boston Seaport.

A thank you to our industry partners:

Discover more CRISP content at the links below

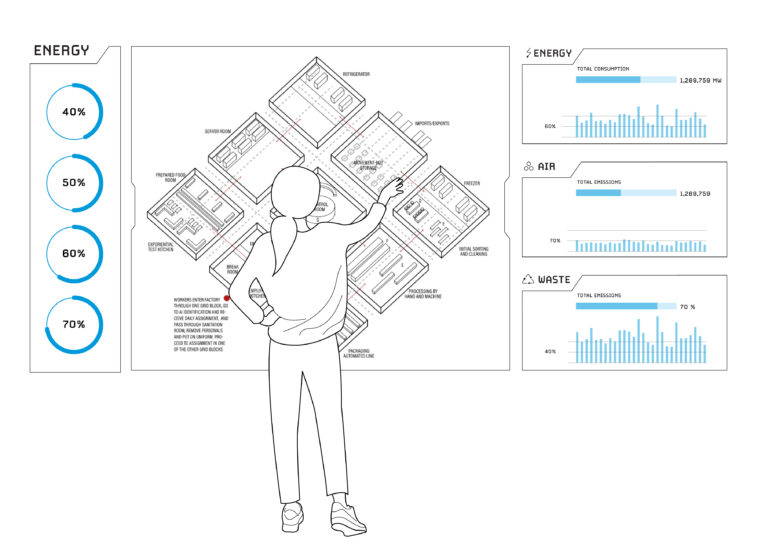

The Factory as Real Time Observatory project looks at tomorrow’s seafood processing plant as a real time observatory that is able to collect as well as publicly display a wide range of real time data about seafood, its origin and the state of seafood populations as part of its everyday operations. The seafood processing plant, in this way, becomes a digital canvas allowing for public engagement as well as joining the network of existing sensor infrastructures that provide insight into the state of our oceans and its wildlife.

Seafood Factory as Real Time Observatory

Team: Kristian Kloeckl, Pat Dawson

Want to Stay Up to Date on the CfD?